DOLPHICAM2

The pelicase contains a connected Black Box, rugged tablet, software and all cables and accessories that are needed for using the dolphicam2 platform, including room for storing three transducer modules.

Description

Pelicase

10” Panasonic FZ-G1 rugged tablet

Black Box

Black Box power supply with international adapters

Box with a screwdriver for USB-Cables

Test and practice material sample

Frame with kickstand

Technical Details

Black Box

PC/Host port USB C

Transducer ports 2x USB C

Encoder ports 2x GPIO

Other connections Ethernet

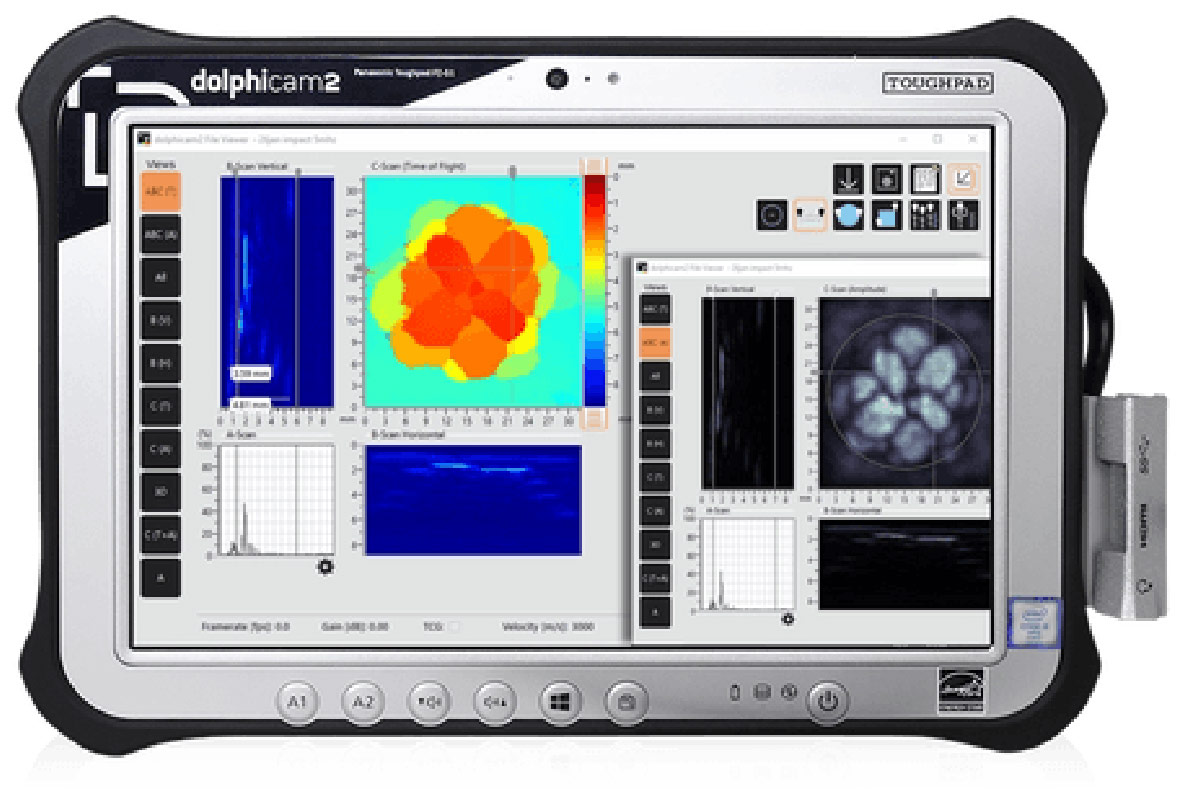

Rugged tablet

Processor Intel 5 CPU, 8GB ram

Ingress protection IP65

Battery life: 6-8 hours (normal use)

Size And Weight

Dimensions:

Black Box and Rugged tablet combined: 300 x 188 x 70mm / 11.8 x 7.4 x 2.7”

Rugged tablet: 185 x 273 x 19mm / 7.2 x 10.74 x 0.7”

Pelicase: 560 x 360 x 230mm / 22 x 14.1 x 9”

Weight:

TRM + USB-C cable: 360g / 0.7lbs

Core Unit (Black Box + Toughpad): 2.6kg / 5.8lbs

System packed in custom pelicase (Working system + 2x charging cables + pelicase): 8.2kg / 18.0lbs

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.