STUDY OVERVIEW

A Scottish inspection company, approached dolphitech with the requirement to perform delamination and thickness checks on polypropylene (PP) lined Glass Fibre Reinforced Polymer (GFRP) pressure vessels in a chemical processing plant. In order to assess the feasibility of the inspection using a dolphicam2, the service provider supplied dolphitech with a reference sample of representative material. This panel was 19mm thick and contained 16mm of structural GRP and 3mm polypropylene lining.

SOLUTION

A TRM-EC-1.5MHz was used to inspect the sample, with this low frequency providing reliable penetration through the 19mm thickness of the pressure vessel material. This TRM has an Aqualene delay line, the surface of which conforms to slightly curved surfaces, making it suitable for inspection of both pipes and vessels with diameters >600mm. The sample was imaged from both GFRP and polypropylene surfaces, representing inspections from the outside and the inside of the pressure vessel respectively.

CHALLENGES

GFRP pressure vessels are known to be challenging for ultrasonic testing, as the different material phases present act to scatter, absorb and deviate the sound beams. In service degradation mechanisms, such as chemical attack or blistering, may exacerbate these issues. Low-frequency probes are therefore required to adequately penetrate through the material, however, this reduces the sensitivity of the inspection.

FINDINGS

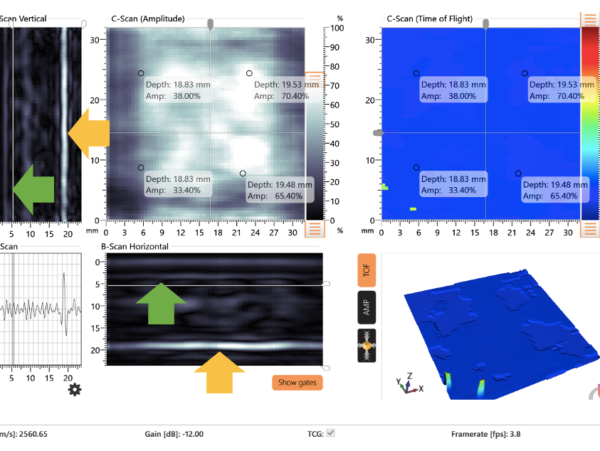

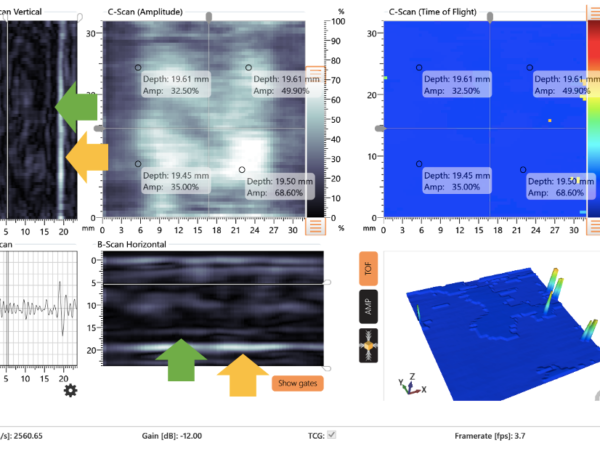

The GFRP to polypropylene panel was successfully inspected from both faces, with reliable backwall echoes observed (yellow arrows), indicating that thickness and delamination checks could be performed on-site. Point markers were dropped on the C-scan images which enabled live measurements of the thickness and the signal amplitudes. From both faces, the internal interface between the polypropylene and GFRP could also be resolved (green arrows).

CONCLUSION

Through this feasibility inspection of a reference sample, dolphitech were able to de-risk the site inspection, giving confidence in the performance of the dolphicam2 to the NDT service provider.

ENERGY MARKET

In the harshest environments onshore and offshore, dolphitech, provides safe and adaptable non-destructive testing platform to the Energy Industry.

Read moreREQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.