STUDY OVERVIEW

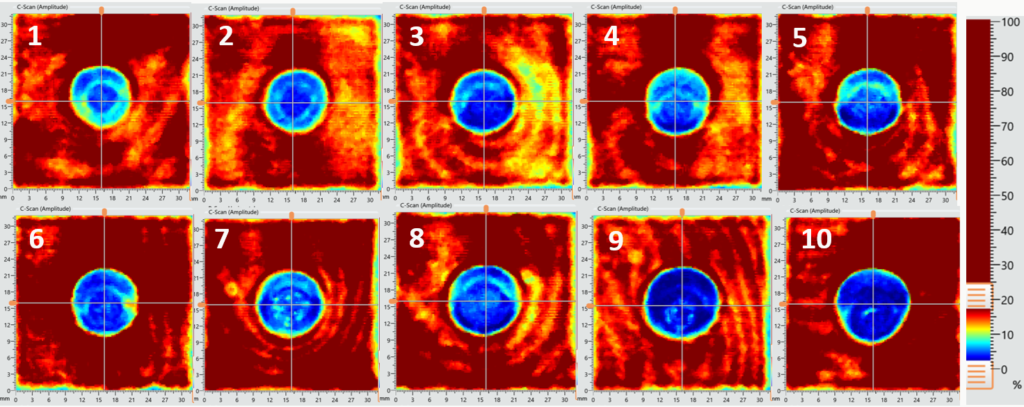

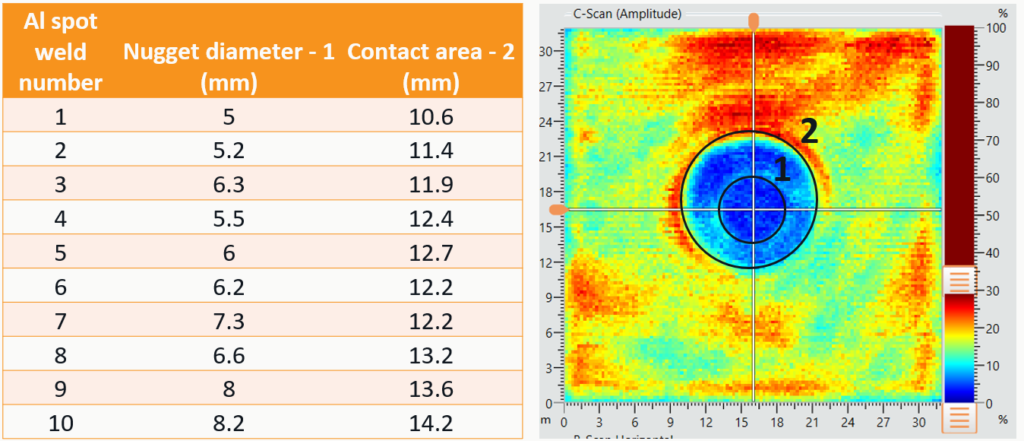

An automotive manufacturer provided dolphitech with a resistance spot-welded aluminum panel to assess inspectability with the dolphicam2. The panel had a total thickness of ~3mm, comprising two 1.5mm sheets. Along its length, ten spot welds of varying nominal nugget diameter had been introduced.

SOLUTION

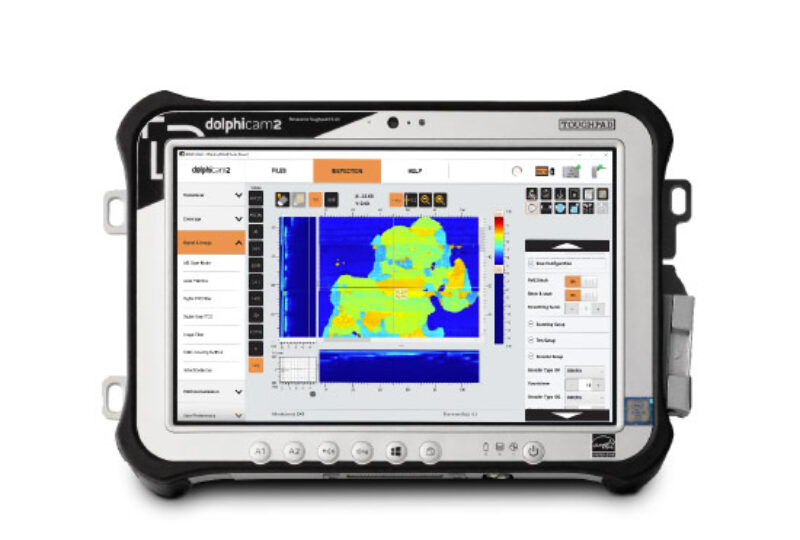

The panel was inspected using a TRM-DA-10MHz Transducer Module (TRM). This TRM is our highest frequency model and therefore provides maximum sensitivity for inspection of thin parts. The 8mm Rexolite delay line provides a wear resistant, hard contact surface, suitable for flat sheet components.

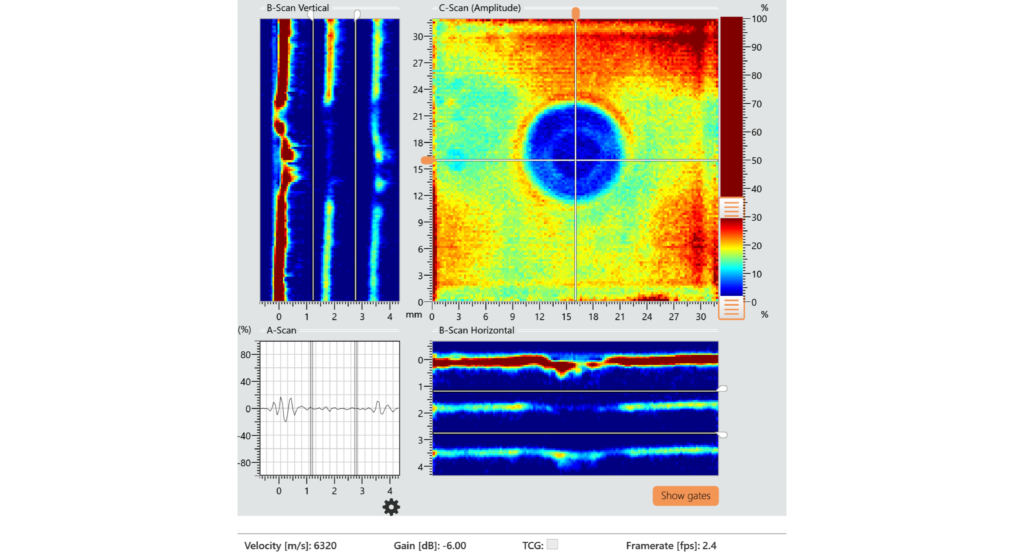

In the dolphicam2 software, the interface between the two sheets was gated, and the data was displayed as an amplitude C-scan. With this data representation the intact weld, where sound is transmitted through the interface, displays a low-amplitude blue color, whereas the non-welded interface, where sound is reflected back to the transducer, displays as a high-amplitude red color.

FINDINGS

The contact area and nugget diameters were successfully resolved and measured for the ten spot welds. The contact area is represented as the larger diameter circle, and corresponds to the area where the two sheets are in intimate mechanical contact. The smaller nugget diameter represents true fusion zone within this contact area, and can be resolved as a lower amplitude, inner circle within the contact area. In the dolphicam2 software, the circular measurement tool was overlaid on the amplitude C-scan to perform the diametric measurements in each instance. As well as diameters, deviations in nugget quality could also be observed, for instance the higher amplitude reflections in Weld #7. This may be indicative of porosity or imperfect fusion in the weld.

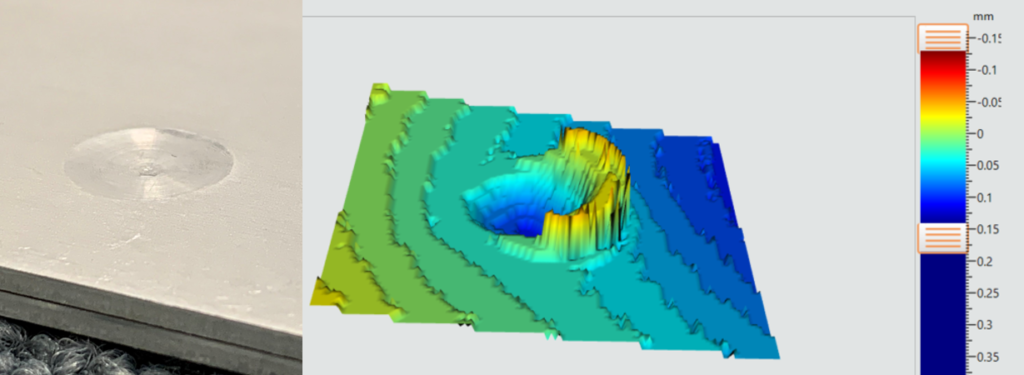

The dolphicam2 can also be used for profilometry of the weld surface if needed. The same dataset can be used, all that is required is to move the gate from the weld interface to the front wall echo. Sub 0.1mm deviations from flat can therefore be highlighted, measured and visualised in 3D.

CONCLUSION

The dolphicam2 with a TRM-DA-10MHz was able to successfully inspect aluminum spot welds. Weld contact area, nugget diameter, nugget quality and surface profile could all be measured from a single dolphicam2 dataset acquired at a single location. Identical settings were used for all welds, demonstrating the reproducibility of the data, and potential for automation. The dolphicam2’s 32x32mm matrix aperture is ideally-suited to this application, since the whole weld can be covered from one location without requirement for any mechanical movement.

AUTOMOTIVE MARKET

Non-destructive testing technology is an important means to improve quality control in the automotive industry. The dolphicam2 benefits aspects such as the manufacturing process and ongoing maintenance.

Read moreREQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.